PROCESS COST OPTIMISATION

Optimised procurement processes enable profits to be maximised. It often costs more to procure C-parts or auxiliary and operating materials than the actual products themselves.That is why we create individual and cost-effective supply concepts for you.

WE USE THE FOLLOWING METHODS:

- Professional C-parts management

- Kanban

- An efficient warehouse management system

C-PARTS MANAGEMENT

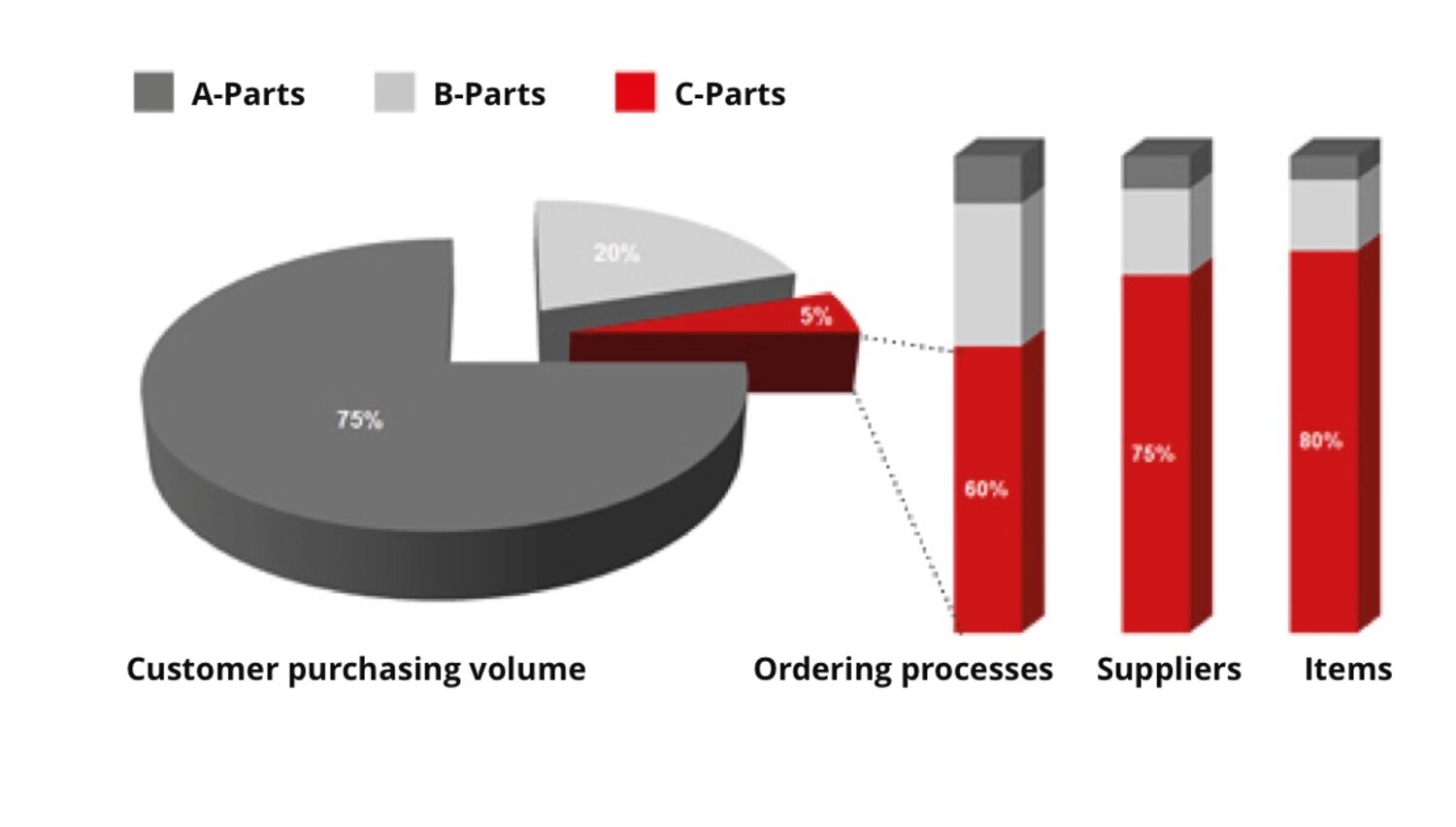

High procurement costs given a low goods value

C-parts are products that cost little themselves. Since they are frequently used and entail a lot of ordering effort, however, their procurement usually costs a disproportionate amount of money.

Professional C-parts management

Efficient C-parts management has the following advantages:

- Optimised stocks

- Increased supply security

- Lower capital commitment

Arrange your support from W.EG. companies. They create delivery concepts tailored to your needs and use advanced warehouse management systems, efficient C-parts management and storage and delivery concepts like kanban to help you achieve even greater success.

WAREHOUSE MANAGEMENT SYSTEMS

Greater structure and more order in your warehouse

It is a clever interplay of several components that makes our advanced warehouse management systems so efficient. We use scanners, software, boxes and special shelving systems to optimise our customers' warehouses. Every customer receives a system that is precisely adapted to their individual needs. Items can thus be stored and made available as required. These measures increase productivity and result in lower process costs.

Our warehouse management services at a glance

- Inventory analysis

- Item identification and integration into the warehouse system

- Demand-oriented shelf planning

- Definition of the minimum/maximum stocks of all items

- Installation and initial equipping of the shelves

- Uncomplicated item ordering using hand-held scanners and barcodes

- Transmission of the order to our online shop

- Delivery of replenishments from our central warehouse

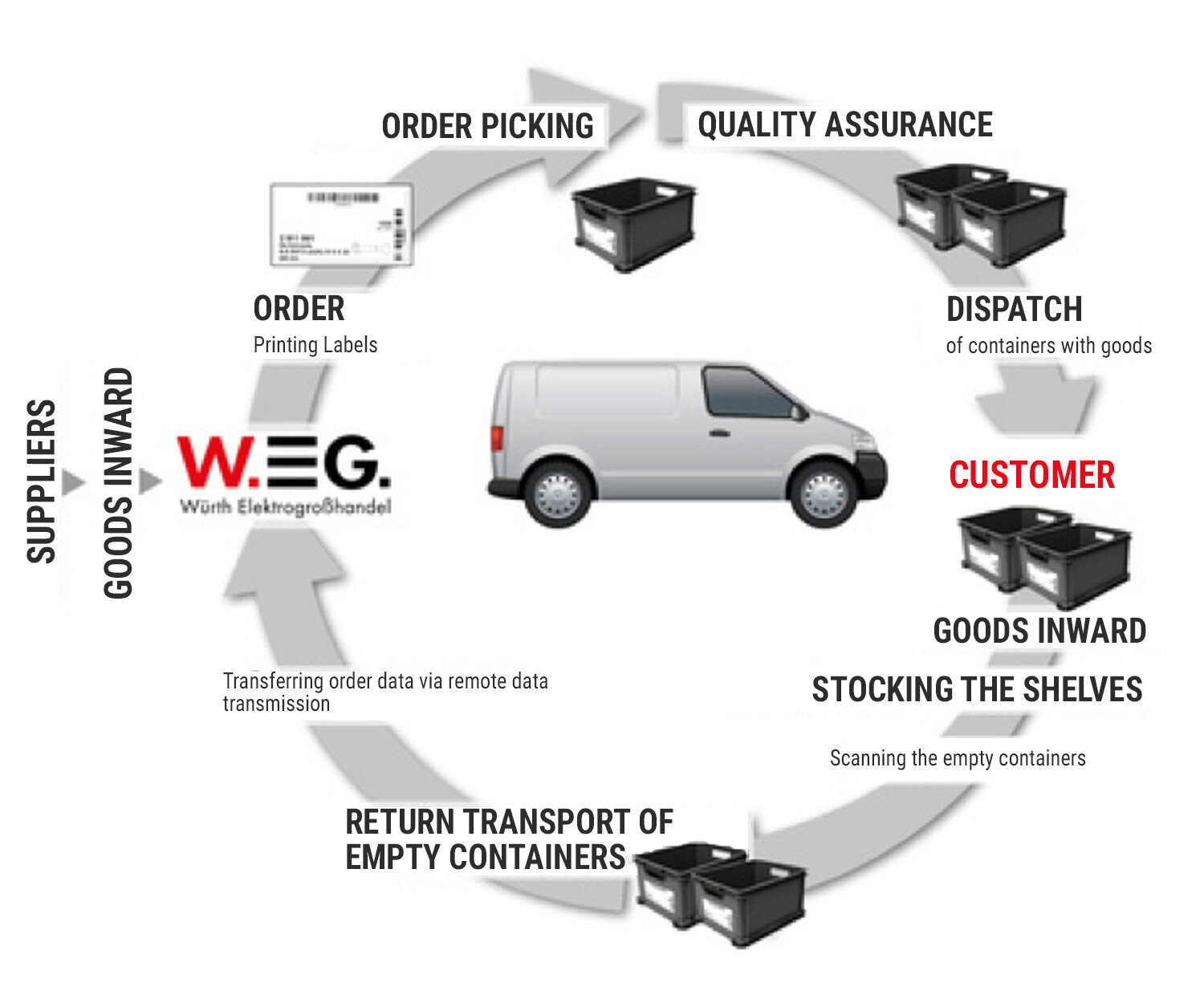

KANBAN

Use kanban to control your production processes

The term originates from Japanese and means something like card, signboard or billboard. The method behind the term also comes from Japan. It is used to coordinate production processes within production facilities.

Modern demand-synchronous production is usually based on the kanban method. It proposes that only those quantities of material which are needed be requested. This results in a reduction of stocks, so capital commitment is also reduced. Although these are only two of the method's objectives. Kanban is also intended to ensure greater production flexibility and optimise the entire production process to make it more cost-effective.